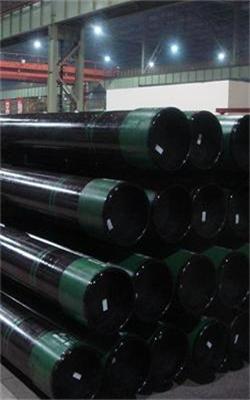

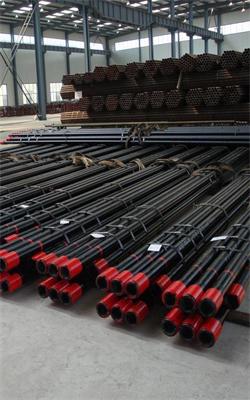

Carcasas

Products: API SPEC 5CT Seamless Steel Tubes

Applications: It is widely used for oil casing and tubing in oil wells

Grades: J55, K55, N80, L80-1, L80-9Cr, L80-13Cr, P110, Q125, K55 D10, L80 D10.

Special Service: Sweet Service, Sour Service, Anti-H2S, NACE MR0175/ISO15156

Produce Process: Hot Rolled, Cold Drawn, Hot Expanded.

Accessories: Pup Joint, Coupling (Coupling Stock), Blast Joint, Crossover etc.

Connection: API connection and Premium connection, like TPCQ, HSM etc.

Dimension Tolerance

| Types of steel tubes |

Outer Diameter |

Wall Thickness |

|

| Cold-rolled tubes |

Tube sizes(mm) |

Tolerances(mm) |

Tolerances(mm) |

| <114.3 |

±0.79 |

-12.5% |

|

| ≥114.3 |

-0.5%,+1% |

||

Chemical Composition

| Standard | Grade | Chemical compositions(%) |

|||||||||

| API SPEC 5CT |

J55 |

C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ | / | |

| N80 |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ | / | / | 0.11~0.16 |

|

| L80 |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ | / | |

| P110 |

0.26~0.395 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08 |

|

Mechanical properties

| Grade | Type | Total elongation under load (%) |

Yield strength (min) |

Yield strength (max) |

Tensile strength min Mpa |

Hardness Max (HRC) |

Hardness Max (HBW) |

| J55 | - | 0.5 |

379 | 552 | 517 | - | - |

| K55 | - | 0.5 |

379 | 552 | 655 | - | - |

| N80 | 1 | 0.5 |

552 | 758 | 689 | - | - |

| N80 | Q | 0.5 |

552 | 758 | 689 | - | - |

| L80 | 1 | 0.5 |

552 | 655 | 655 | 23 | 241 |

| L80 |

9Cr | 0.5 |

552 | 655 | 655 | 23 | 241 |

| L80 |

13Cr | 0.5 |

552 | 655 | 655 | 23 | 241 |

| C90 | - | 0.5 |

621 | 724 | 689 | 25.4 | 255 |

| C95 | - | 0.5 |

655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | All | 0.65 | 862 | 1034 | 931 | - | - |